Thepa ea tungsten carbide rod le ts'ebeliso ea eona Tungsten carbide kapa carbide e entsoeng ka samente e na le litšobotsi tse ngata tse ntle joalo ka boima bo phahameng, matla a matle, moaparo o motle le ho hanyetsa kutu le botsitso bo matla tlas'a mocheso o phahameng le ho 500 ° C.E lula e sa fetohe mme esita le ho 1000 ° C e fumana boima bo phahameng.

Lithupa tse entsoeng ka samente tsa Tungsten Carbide li tšeloa ka har'a HIP Furnace 'me li entsoe ka thepa e tala ea 100% e kenyelletsang WC le CO.

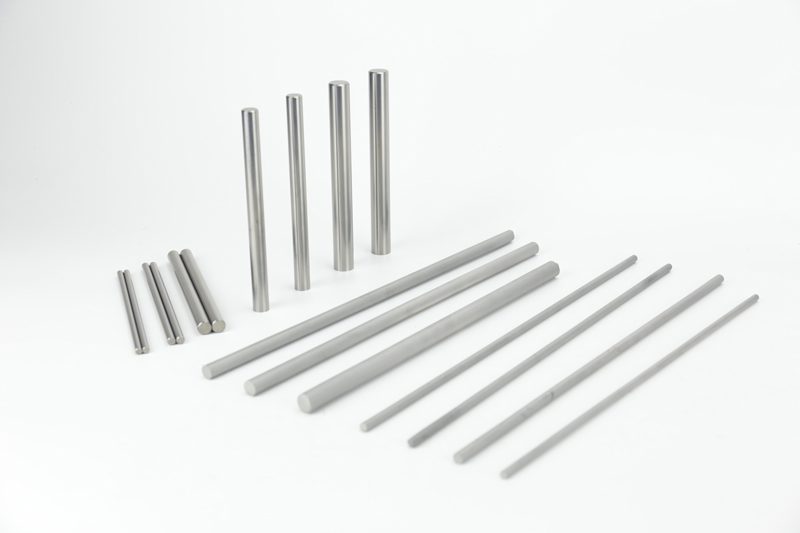

Hangata ho na le mefuta e meraro ea lithupa tse entsoeng ka samente tsa tungsten carbide joalo ka molamu oa PCB, molamu o se nang letho, le molamu.

Bongata ba ts'ebeliso ea eona ke tlhahiso ea lisebelisoa tsa ho seha bakeng sa tšepe, hammoho le lehong, lipolasetiki le lisebelisoa tse ling le liindasteri tse hlokang maemo a phahameng a thata, ho hanyetsa le ho hanyetsa ho bola.

Tungsten carbide rod e na le litšoaneleho tse ngata tse ikhethang, ho kenyelletsa le maemo a phahameng a thata le matla, ho hanyetsa ho hoholo ho apara le ho senya, le botsitso bo tsotehang le ha mocheso o le holimo.Tšepe e entsoeng ka tšepe, litšepe tse se nang tšepe, lipolasetiki, fiber ea lik'hemik'hale, tšepe e sa hloekang le tšepe e phahameng ea manganese ke tse ling tsa lintho tse ka sehoang ka sesebelisoa sena.Ho feta moo, e ka sebelisoa ho etsa lisebelisoa tsa ho cheka, lisebelisoa tsa merafo, likarolo tsa ho roala, li-bearings tse nepahetseng, li-nozzles le hlobo ea tšepe, har'a lintho tse ling.

Mona ke mehato e meng ea ho hlahisa lithupa tsa tungsten carbide.

1) Moralo oa Kereiti

Kereiti e entsoeng ke feme ea rona: SK10, SK30, SK35B, SK35, SK45 joalo-joalo.

Khothaletsa Kereiti e nepahetseng bakeng sa ts'ebeliso ea lithupa tsa tungsten carbide.

2) RTP Ball Milling

Leloala le silang bolo le na le bokhoni ba ho etsa phofo ea boholo bofe kapa bofe ba lijo-thollo, ho kenyeletsoa phofo e ntle le e ntle haholo ho tsoa linthong tse kopaneng tsa phofo ea WC, phofo ea cobalt le lisebelisoa tsa doping.

Spray -Drying Process

E le ho netefatsa hore thepa e hloekile ka ho feletseng, tora ea prilling e fafatsoa ka ho omisa spray.

3) Extrusion kapa Tobetsa Tobetsa

Mekhoa e 2 e fapaneng ea ho hlahisa lithupa tsa carbide.

4) Mokhoa oa ho omisa

5) Sintering

Lehare le fumana kalafo ea mocheso ka mocheso oa likhato tse 1500 tsa Celsius ka nako ea lihora tse 15.

6) Machining

Moreki o hloka sebaka sa H5 / H6 fatše, ebe re tla sebetsana le lithupa tsa carbide ka ho sila ho se nang setsi.

7) Tlhahlobo ea Boleng le Tlhahlobo

Ho lekola ho otloloha, boholo, le ts'ebetso ea 'mele joalo ka TRS, Hardness le ponahalo ea lithupa tsa carbide jj.

8) Ho paka

Paka lithupa tsa carbide ka lebokoseng la polasetiki le nang le lengolo ho lona.

Nako ea poso: Mar-04-2023